[The following article by Raynard Churchwell with photo by Darnell Wilburn Jr first appeared on the Kennesaw State University website, republished with permission]

Each year, Georgia quarries generate millions of tons of leftover byproducts called pond screenings, much of which sits unused in large holding ponds. At Kennesaw State University, associate professor Jayhyun Kwon is working to turn this overlooked material into a construction industry resource.

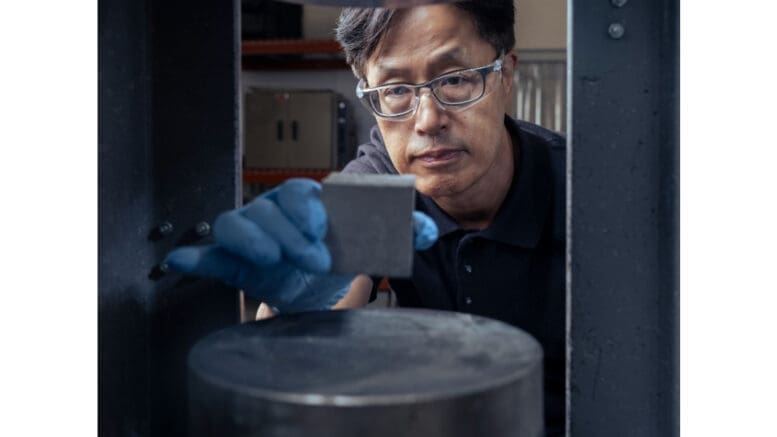

Kwon’s research focuses on reducing waste before recycling is required. His team, working out of KSU’s Soil and Materials Lab on KSU’s Marietta Campus, is studying ways to use quarry pond screenings as a substitute for fly ash, a material commonly used as a mineral filler in asphalt binders and concrete. With fly ash supplies fading, finding a local and sustainable alternative could have significant impacts for Georgia’s construction industry.

“Right now, about 2.2 million tons of pond screenings are generated annually in Georgia,” said Kwon, who is an associate professor in the Southern Polytechnic College of Engineering and Engineering Technology (SPCEET). “If we can find a way to integrate this material into asphalt and concrete without sacrificing performance, we not only reduce the amount of waste sitting in these ponds but also lower material costs for construction projects.”

Inside the Soil and Materials Lab, graduate research assistants and undergraduate student assistants are testing mixtures, carefully measuring how the addition of pond screenings affects strength, durability, and workability. Kwon said the hands-on experience is invaluable for students, preparing them for careers in civil engineering while allowing them to contribute to a project with real-world environmental and economic impact.

The potential benefits go beyond sustainability. By finding a market for underused quarry byproducts, aggregate producers could modify their processes to collect and sell screenings rather than discard them. Construction companies could save on materials while earning environmental credits, an advantage when bidding on government-funded infrastructure projects that require green building standards.

“It’s a win-win,” said Kwon, who previously served as application technology manager at Tensar International Corp., a leading geosynthetics manufacturer and provider of ground stabilization solutions. “You save cost, reduce waste, and meet environmental requirements.”

Before the material can be used in industrial settings, there are still some hurdles to clear. Kwon said that the material itself poses challenges due to its fine, dust-like nature. Acceptance of it will depend on approval from agencies such as the Georgia Department of Transportation.

“This is a feasibility study, and there’s limited guidance on how to use this material,” he said. “But if we can demonstrate that it works, I believe the industry will be quick to adopt it.”

As his team prepares for future field trials, Kwon is optimistic about the long-term impact of the research. He hopes this work will serve as a model for other states and encourage further exploration into the reuse of industrial byproducts.

“Once people see that this works, they will start finding new uses we have not even considered yet,” he said. “This is just the first step toward a cleaner, more sustainable future for construction.”

Recognizing the importance of Kwon’s work, SPCEET administrators have expressed strong support for the project and its potential impact.

“Research like Professor Kwon’s perfectly reflects the mission of the Southern Polytechnic College of Engineering and Engineering Technology,” SPCEET Dean Lawrence Whitman said. “We lead the way in supporting innovative work that not only solves practical engineering challenges but also provides our students with industry-relevant training that prepares them to be leaders in sustainable infrastructure development.”

Story by Raynard Churchwell

Photos by Darnell Wilburn Jr.